In the pharmaceutical industry, ensuring the quality and integrity of vials and their contents is paramount. To meet these rigorous standards, vial inspection machines have become indispensable tools. These high-tech devices not only enhance production efficiency but also guarantee product safety by conducting comprehensive inspections.

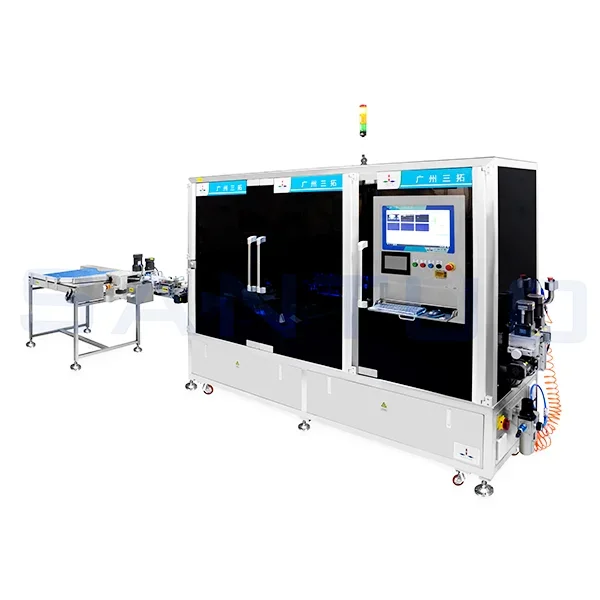

1. Introduction to Vial Inspection Machines

Vial inspection machines are automated systems designed to scrutinize vials. They utilize advanced imaging technologies, sensors, and algorithms to detect defects and anomalies that could compromise product quality. From visual inspections of vial appearances to sealing integrity checks, these machines ensure that only flawless vials proceed to the next stage of production.

2. Comprehensive Inspection Content

2.1 Appearance Inspection

One of the fundamental aspects of vial inspection is the appearance check. This includes verifying the clarity and cleanliness of the vial, ensuring there are no scratches, chips, or discolorations. The vial inspection machine employs high-resolution cameras and sophisticated image processing software to capture and analyze these details accurately.

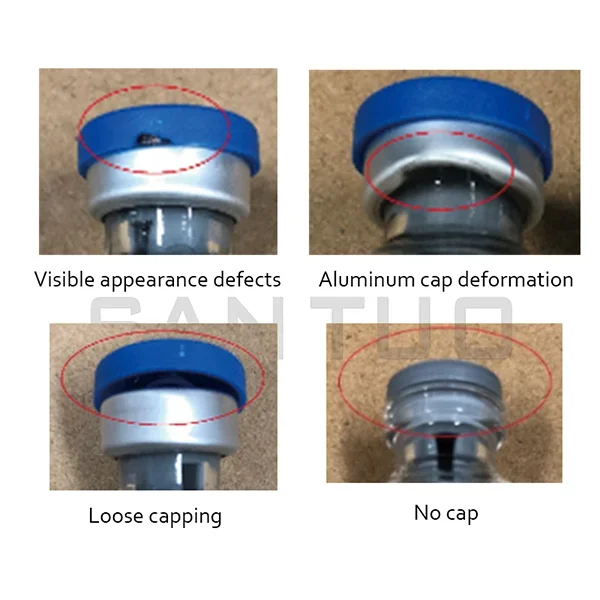

2.2 Crimp Cap Integrity

The crimp cap, which seals the vial, plays a crucial role in maintaining product sterility and integrity. The vial inspection machine can detect whether the crimp cap is intact and properly seated. It uses machine vision to inspect the uniformity and tightness of the crimp, ensuring there are no gaps or weaknesses that could lead to contamination or leakage.

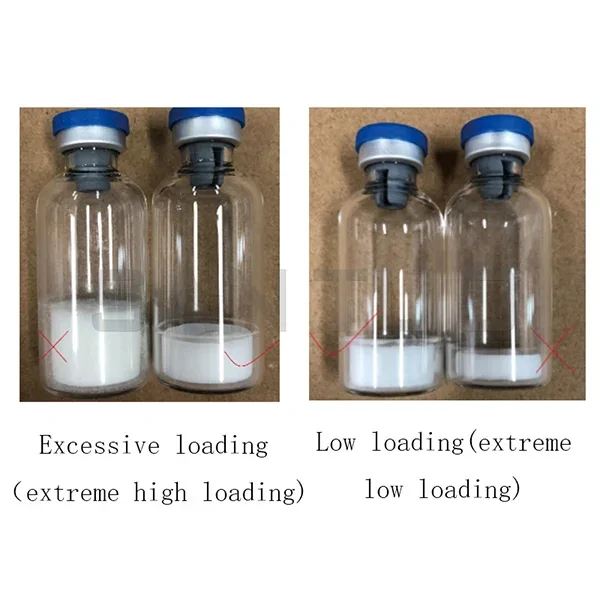

2.3 Powder Quantity and Presence

In vials containing powdered medications, ensuring the correct quantity of powder is vital. The vial inspection machine employs machine vision to take photos, the software analyzes and identifies that each vial contains the prescribed amount of powder. It can also detect the presence of powder in vials that should be filled and alert operators to any missing or insufficient powder quantities.

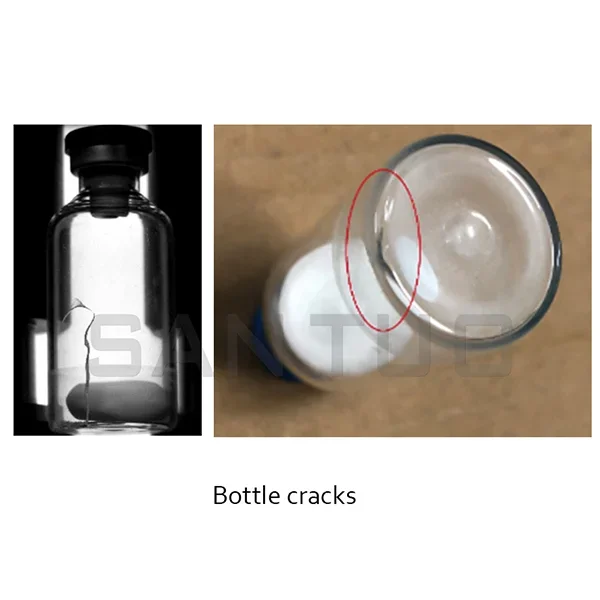

2.4 Crack Detection

Cracks in vials can occur during manufacturing or handling, compromising their structural integrity and potentially leading to contamination. The vial inspection can inspect even the smallest cracks, which ensures that only structurally sound vials are used for packaging.

2.5 Defects Related to Rubber Stoppers

Rubber stoppers are another critical component in vial sealing. They must be present, properly positioned, and free of defects such as tears, punctures, or contamination. The vial inspection machine includes specialized sensors and imaging systems to inspect the rubber stoppers thoroughly. These systems can detect even minute imperfections that could affect the seal's effectiveness.

3. Advanced Technologies in Vial Inspection Machines

To meet the ever-increasing demands for quality and efficiency, vial inspection machines incorporate cutting-edge technologies. Machine learning algorithms, for instance, enable the machines to learn and adapt to variations in vial types and defects over time. This improves inspection accuracy and reduces false positives or negatives.

Automated defect classification systems further streamline the inspection process by categorizing detected defects in real-time. This allows operators to quickly identify and address issues, minimizing downtime and waste.

4. The Importance of Comprehensive Inspection

Comprehensive vial inspection is not just a regulatory requirement; it's a matter of patient safety. Defective vials can lead to contaminated medications, which can have severe health consequences. By employing vial inspection machines that cover all aspects of vial quality, pharmaceutical companies can ensure that their products meet the highest standards of safety and efficacy.

Moreover, these machines contribute to operational efficiency by reducing manual inspection time and minimizing human error. They provide consistent and reliable inspection results, enabling companies to maintain a high level of quality control throughout the production process.

5. Conclusion

From appearance to sealing, vial inspection machines conduct a comprehensive range of inspections to ensure the quality and integrity of pharmaceutical vials. Their advanced technologies, including high-resolution imaging, sensors, and machine learning algorithms, enable them to detect even the smallest defects with remarkable accuracy. By focusing on critical details such as crimp cap integrity, powder quantity, crack detection, and rubber stopper inspection, these machines play a vital role in safeguarding patient safety and maintaining operational efficiency.

In an industry where quality cannot be compromised, vial inspection machines are indispensable tools that continue to evolve and improve, meeting the challenges of modern pharmaceutical production.

https://www.santuomachine.com/comprehensive-inspection-content-of-vial-inspection-machine.html