Lightweight, durable and cost-effective materials are becoming increasingly popular in today’s rapidly progressing industrial world. One such astonishingly in demand product is the HDPE sheet, a thermoplastic that comes from high density polyethylene. They are recommended for packaging of products, automotive, agriculture, constructions and in the marine industry thanks to its low cost compared to other rigidity materials. If what you are looking for is an environmentally sustainable way to solve your durability and chemical resistance problems, or even if all you want is a tough plastic material that can stand up to impacts, HDPE may be the solution.

Features That Set HDPE Sheets Apart

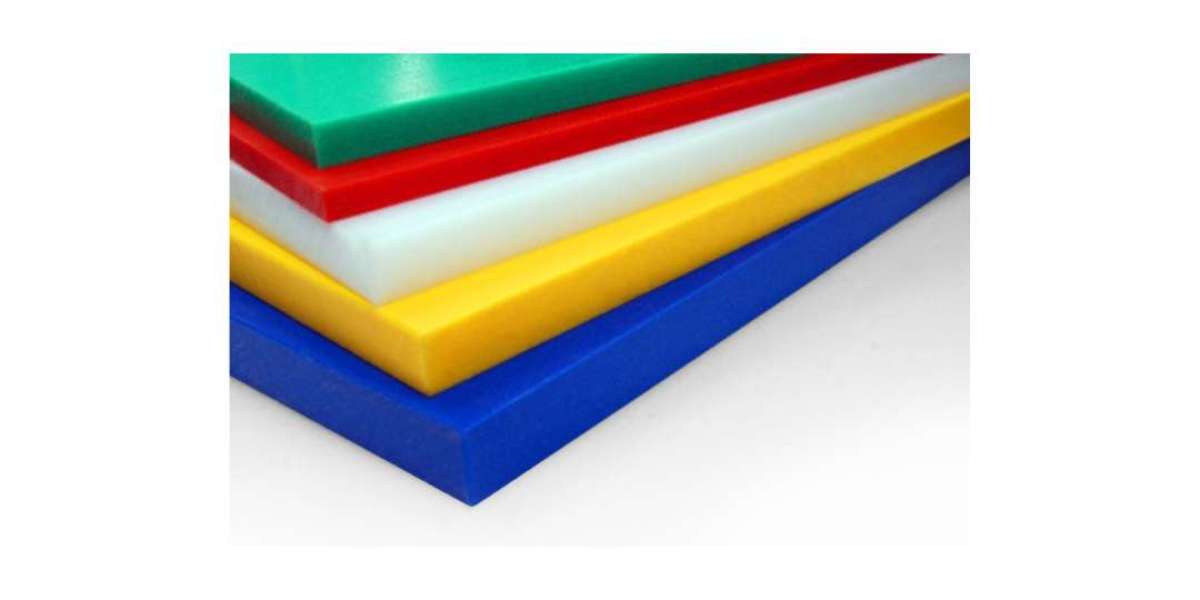

HDPE Plastic Sheets and Their Benefits W hat make HDPE plastic sheets so great is that their composition. These sheets are strong lightweight materials that can either be glued, taped or fastened to any surface. HDPE is non-toxic and food-safe, so it is safe for use in the packaging of foods or as cutting boards without worrying about the health effects. It's resistant to moisture, chemicals, UV light and corrosion so it will serve you well in even the toughest conditions. HDPE Sheets in Industry HDPE (High-Density Polyethylene) sheets are a versatile solution for use across numerous industries. In the packaging, construction materials and chemical processing markets it is used for applications that need to withstand moisture (including intermittent water exposure) or chemicals.

Uses of HDPE Sheets According to the Industry

HDPE Sheeting Provider You don’t know how many industries use HDPE sheets. Used in construction as a vapor barrier. They are utilized for canal linings and silage covers in agriculture. The sea industry for dock fenders, and boat pieces uses HDPE sheets because they resist saltwater. On the other hand, containers, bottles and trays are produced by packaging industry using HDPE sheets.

Selecting the Correct HDPE Sheet Manufacturer

Deciding on a dependable HDPE sheet manufacturer is key, when it comes to purchasing ideal quality of HDPE sheets. Benign supplier not only provides superior quality products, but also consistent product thickness, color and durability. The top-rated suppliers offer custom services to tailor product design and functionality according your specific project needs. You should always be on the lookout for certifications, production standards and customer reviews before you purchase.

Understanding HDPE Sheet Price Factors

One of the frequently asked question from buyers is about HDPE sheet price. HDPE Sheets Price List Cost of/4sheet in India The price range is indicative and varies based on thickness, size as well color type such as virgin/recycled. The other factors affecting pricing are mass discounts, shipping expenses and custom requirements. Recycled HDPE sheets cost less, but virigin HDPE is stronger and more durable.

Reliable HDPE Plastic Sheets Manufacturers in India

In India we have developed kind of network to supply HDPE plastic sheets in domestic as well international market. These vendors cater to different fields which includes food processing, automotive and construction. The top suppliers for some of the leading Indian companies are precision work, quality control and timely delivery. Now, as the government is focusing on Make in India many suppliers provide international quality standards while manufacturing HDPE sheet so that Indian customers get world class.

How to Keep your HDPE Sheets Lasting Long

Although HDPE sheets are durable, the service life will be axa==ffaxggformGB.5ex70p4the Minlon lengthened if they're well-maintained.. HDPE sheets should be kept out of direct sunlight in a cool dry place at all times to avoid warping or quality degradation. Never use a harsh cleaner or metal brushes, as these can scratch the surface. When working in industrial environments with HDPE sheets,

The Rising Need for HDPE Sheets in India

As industries in India thrive, experts predict a big jump in the need for HDPE sheets. City growth new farming methods, and fresh ideas in packaging are behind this increase. India is also becoming a top seller of HDPE sheets sending products to Southeast Asia, the Middle East, and Europe. Because of good hdpe sheet prices and the ability to make a lot Indian makers are starting to compete worldwide.

Conclusion

In Summary: HDPE sheets aren’t just a plastic product – they’re the solution to preserving our environment, ensuring flexible use and lasting durability. If you’re in the market for building supplies, packaging materials or industrial products, HDPE sheet price might just be a perfect fit. Whether you’re researching high-density polyethylene (HDPE) home depot plastic, sources for your hdpe sheet supplier needs or even the current FOB and regional price trends in the HDPE market, doing an informed study can be quite complicated. As technology advances, HDPE sheets will still be a critical part of the processing capabilities. These sheets are lightweight and durable so that they can be put to use immediately without any break-in period, unlike traditional glass construction. Offered in various thicknesses and sizes, they are recyclable. And, in India too they are increasingly gaining popularity as more and more businesses shift to low cost flexible solutions.

Frequently Asked Questions

Q1: What are available standard sizes and thicknesses for HDPE sheets?

A: Normally, we have 4x8 feet size for HDPE sheets or depend on custom design.Adopt extrusion craft production.please according to your application decide the thickness.

Q2 : Where is the best place to get HDPE plastic sheets in India?

A: Yes, reliable sources are available in industrial clusters such as Gujarat, Maharashtra and Delhi wherein you can find vendors who deal with standard/ customized HDPE sheets.

Q3: Who is the biggest manufacturer of HDPE sheets?

A: Singhal Industries Pvt. Ltd – The premier HDPE sheet suppliers in India Jain Irrigation Systems Limited is an entirely customer-focused company involved in producing and distributing new-age Plastic Products for making irrigation more efficient. Company has grown over the time, by acquiring sophisticated machinery as well as developing its own unique infrastructures such as high-speed sheet extrusion lines coating & lamination units and diversified packing operations since establishment in 1987.